Introduction

Load cells are essential components in industrial and commercial weighing applications. Among the various types available, Single Ended Shear Beam Load Cells stand out for their accuracy, durability, and adaptability in medium-to-high-capacity weighing systems. But why should you choose a single ended shear beam load cell over other types? This article explores its advantages, working principles, and how it compares to double ended shear beam load cells.

Understanding the Shear Beam Load Cell Working Principle

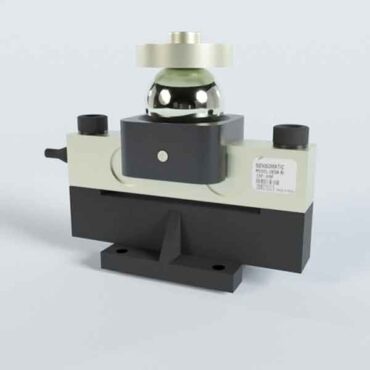

A shear beam load cell operates on the principle of shear strain measurement. It consists of a strain gauge mounted on a metal beam, which deforms under applied force. This deformation alters the electrical resistance, which is then converted into a measurable output signal, providing precise weight readings. This technology ensures high accuracy and reliability in load measurement.

What is a Single Ended Shear Beam Load Cell?

A single ended beam load cell is a type of load sensor that is fixed at one end and loaded at the other. Typically constructed from alloy steel or stainless steel, these load cells offer excellent resistance to environmental conditions. They are widely used in applications such as platform scales, hopper weighing, and conveyor belt scales due to their compact design and high accuracy.

Key Benefits of Single Ended Shear Beam Load Cells:

- High Accuracy: It provides precise weight measurements essential for industrial and commercial applications.

- Durability: Made from robust materials, ensuring longevity even in harsh environments.

- Versatility: Suitable for various applications, including tank and silo weighing.

- Ease of Installation: Simple mounting and integration into existing weighing systems.

- Cost-Effectiveness: More affordable than other load cell types while maintaining high performance.

Single Ended vs. Double Ended Shear Beam Load Cells

Double Ended Shear Beam Load Cell Working

Unlike single ended versions, a double ended shear beam load cell is supported at both ends and loaded at the center. This configuration makes it ideal for heavier loads, such as truck scales and industrial weighing bridges.

Comparison:

| Feature | Single Ended Shear Beam Load Cell | Double Ended Shear Beam Load Cell |

| Load Capacity | Medium to high | High to very high |

| Installation | Easier, single mounting point | Requires mounting at two points |

| Stability | High accuracy for small-to-medium loads | More stable for large loads |

| Cost | More affordable | Higher cost due to complex installation |

For most industrial and commercial applications, Single Ended Shear Beam Load Cells provide a perfect balance of precision, durability, and cost-effectiveness.

Choosing the Best Load Cell Manufacturers in India

Selecting a reliable manufacturer is crucial to ensure quality and longevity. The Best Load Cell Manufacturers in India provide high-quality single ended and double ended shear beam load cells, ensuring accurate and consistent performance. Look for manufacturers that offer:

- Certified and tested load cells

- High-quality materials

- Customization options for specific applications

- Excellent customer support and after-sales service

Frequently Asked Questions (FAQs)

1. What is the main difference between single ended and double ended shear beam load cells?

Single ended shear beam load cells are fixed at one end and loaded at the other, making them ideal for medium-to-high capacity applications. Double ended shear beam load cells, on the other hand, are supported at both ends and loaded at the center, making them better suited for very high load applications such as truck scales.

2. Where are single ended shear beam load cells commonly used?

They are commonly used in industrial weighing applications such as platform scales, hopper weighing systems, tank and silo weighing, and conveyor belt scales.

3. How accurate are single ended shear beam load cells?

These load cells provide high accuracy and repeatability, making them suitable for industrial and commercial applications where precision is crucial.

4. What materials are used in manufacturing single ended shear beam load cells?

Most single ended shear beam load cells are made from alloy steel or stainless steel to ensure durability and resistance to harsh environmental conditions.

5. How do I choose the best load cell manufacturer in India?

When selecting a manufacturer, consider factors such as certification, material quality, customization options, and after-sales support to ensure you get a high-quality product.

Conclusion

A single ended shear beam load cell is an excellent choice for industries requiring precision, durability, and ease of installation. While double ended shear beam load cells are preferable for extremely high loads, single ended models offer a cost-effective and reliable solution for most medium-to-high capacity weighing needs. Choosing the right load cell and a reputable manufacturer ensures optimal performance in your industrial applications. If you’re looking for high-quality shear beam load cells, source them from the best load cell manufacturers in India for reliable and long-lasting solutions.