The correct weight of the stainless steel strip is a must for the material to meet all the project requirements and to handle the material properly during transportation, processing, and installation. Various simple and effective formulas exist for the weight of a GI strip calculator used in stainless steel applications. Thus, one can ascertain the material quantity needed and estimate costs by correctly using such a formula.

The weight of a GI (Galvanized Iron) strip, including its stainless steel variants, is a key factor in various industries, from construction and automotive to aerospace. Properly calculating the weight of a GI strip is crucial for cost estimation, handling, transportation, and material efficiency. This can be achieved using the GI strip weight formula, which takes into account the strip’s dimensions and the density of the material. Understanding how to apply this formula effectively can lead to more efficient use of materials, improved quality control, and reduced waste in production processes.

The GI Strip Weight Formula

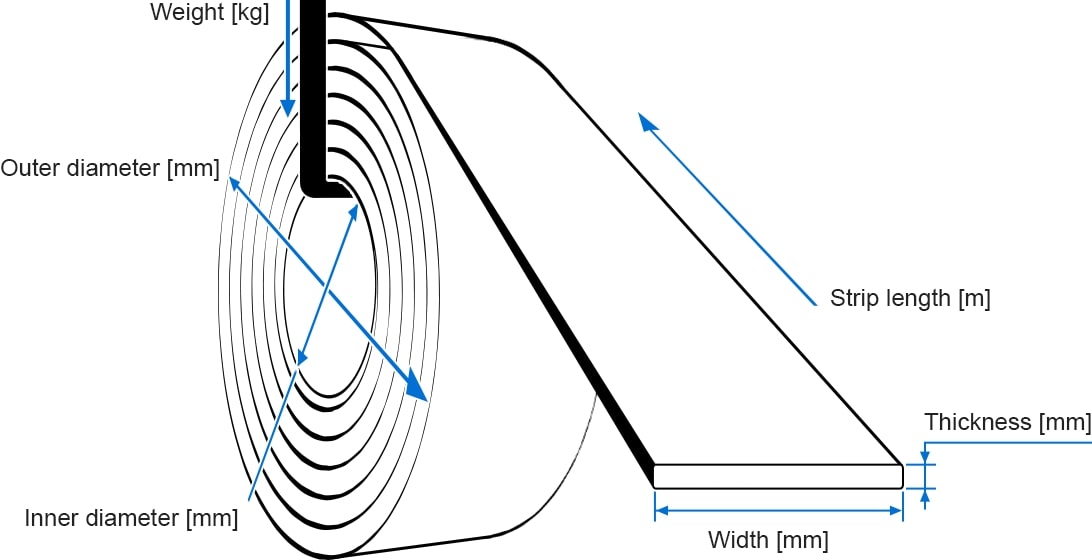

To calculate the weight of a GI strip, you can use the following formula:

Weight (kg)

=

Length (m)

×

Width (m)

×

Thickness (mm)

×

Density (g/cm³)

1000

Weight (kg)=

1000

Length (m)×Width (m)×Thickness (mm)×Density (g/cm³)

Where:

Length (m) is the length of the GI strip in meters.

Width (m) is the width of the strip, also measured in meters.

Thickness (mm) is the thickness of the strip in millimeters.

Density (g/cm³) refers to the material’s density. For stainless steel, the density is typically around 7.85 g/cm³.

By applying this formula, you can determine the weight of a GI strip based on its dimensions and the material it is made from. This is especially useful when working with stainless steel strips, which are commonly used in construction, automotive, aerospace, and other industries.

Breaking Down the Formula

Let’s break down the formula and understand its individual components:

Length (m): The length of the GI strip is a straightforward measurement that you take in meters. It represents the total length of the material, which is essential for calculating the overall weight.

Width (m): The width of the strip is also measured in meters and is important for calculating the surface area of the strip. The wider the strip, the greater its weight will be.

Thickness (mm): The thickness of the strip, measured in millimeters, determines how much material is present in the strip. Thicker strips will naturally weigh more than thinner ones, and this measurement is crucial for determining the weight per unit.

Density (g/cm³): The density of the material is a critical factor because it determines how much mass exists in a given volume of the material. For stainless steel, the typical density is 7.85 g/cm³, though this can vary slightly depending on the specific alloy. The denser the material, the heavier the strip will be for the same dimensions.

After substituting the values into the formula, you can determine the weight of the strip in kilograms.

Why Accurate GI Strip Weight Matters for Stainless Steel Applications

1. Cost Estimation:

Accurate weight calculations are essential for cost estimation. Knowing the weight of the GI strip before purchasing helps businesses avoid over-ordering, thus minimizing excess material costs. Whether you’re working in construction, manufacturing, or another sector, understanding how much material is required ensures you purchase just the right amount for your project.

2. Handling and Transportation:

Stainless steel strips, especially large ones, can be quite heavy. Accurately calculating the weight allows you to determine the proper equipment needed to handle and transport the material. For instance, forklifts or cranes might be required for larger quantities of steel, and this ensures safe and efficient transportation.

3. Material Efficiency:

Calculating the weight of each GI strip helps optimize material usage, reducing waste during production. Whether you’re cutting, bending, or welding, knowing the weight allows manufacturers to plan precisely, ensuring that no material is wasted and that the right amount of steel is used in each project.

4. Quality Control:

Accurate weight calculations are also vital for quality control. When all units of a product weigh the same, it ensures consistency across the board. For instance, industries like automotive, aerospace, and construction, which require strict adherence to standards, benefit from uniform material weights, ensuring each component meets quality standards.

Example Calculation for Stainless Steel Applications

Let’s consider an example of calculating the weight of a stainless steel GI strip with the following dimensions:

Length = 2 meters

Width = 0.3 meters

Thickness = 1.5 mm

Density = 7.85 g/cm³

Substituting these values into the formula:

Weight (kg)

=

2

×

0.3

×

1.5

×

7.85

1000

Weight (kg)=

1000

2×0.3×1.5×7.85

Weight (kg)

=

7.065

1000

Weight (kg)=

1000

7.065

Weight (kg)

=

7.065

kg

Weight (kg)=7.065kg

So, the weight of this GI strip would be approximately 7.065 kg.

Applications of Accurate GI Strip Weight Computation

1. Construction Materials:

In construction, knowing the weight of GI strips is crucial for determining the material needed for structural reinforcement, sheet metal products, and more. It helps architects and engineers plan precisely for the amount of steel to order, ensuring that projects are completed on time and within budget.

2. Automotive Industry:

In the automotive sector, GI strips are used to manufacture various car parts. Accurate weight calculations ensure that the right quantity of material is used, minimizing waste and reducing production costs. It also ensures the efficiency and integrity of components.

3. Piping Systems:

GI strips are widely used in piping systems, including flanges and valves. Accurate weight calculations ensure that enough material is available for fabrication, helping engineers create precise components for systems like water pipelines, oil rigs, and gas lines.

4. Appliance Manufacturing:

In the appliance industry, stainless steel parts are common. Knowing the weight of the GI strip helps manufacturers order the correct amount of material, maintain production efficiency, and avoid delays caused by insufficient material supplies.

Conclusion

The weight calculation of GI strips, especially when working with stainless steel, is an essential process for industries relying on accurate material estimation, handling, and production. Using the correct formula to calculate GI strip weight ensures better material efficiency, quality control, and cost management, making it an indispensable tool in manufacturing processes. By mastering this calculation, companies can optimize their operations and achieve better results across a variety of industries.

For those looking to purchase high-quality GI strips or need assistance with weight calculations, it’s crucial to work with reliable suppliers who offer precise measurements and excellent material quality.