Procurement Resource, a trusted name in market research and procurement intelligence, proudly presents its latest Trichloroethylene Manufacturing Plant Report. This in-depth analysis is a must-read for entrepreneurs and industry players looking to establish a robust trichloroethylene production unit. The report offers vital insights into market trends, plant setup requirements, cost structures, and growth opportunities, helping businesses make well-informed investment decisions.

Trichloroethylene: A Versatile Industrial Solvent

Trichloroethylene (TCE) is a widely used industrial solvent with the chemical formula C2HCl3. Known for its excellent degreasing properties and chemical stability, TCE is commonly utilized in metal cleaning, adhesives, chemical synthesis, and refrigerants. Its demand is continuously driven by industries such as automotive, electronics, and aerospace, where high-performance solvents are crucial for operational efficiency. With sustainability efforts gaining traction, companies are also exploring eco-friendly TCE applications, enhancing its market potential.

Comprehensive Manufacturing Plant Report for Informed Decision-Making

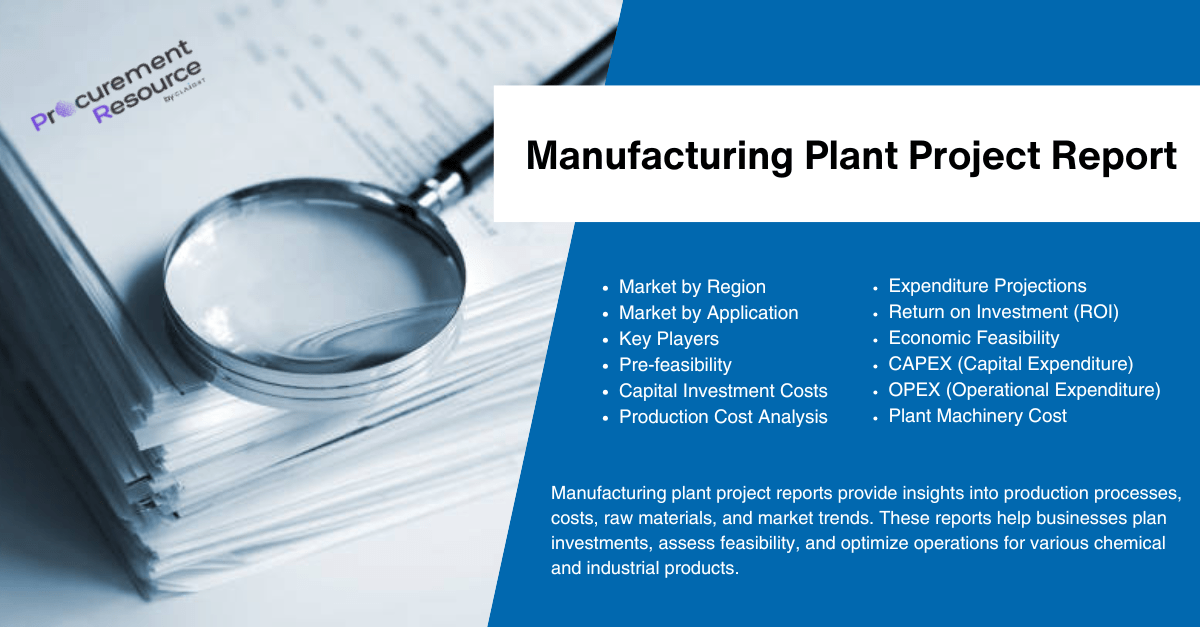

Procurement Resource’s detailed report provides a complete roadmap for setting up a trichloroethylene manufacturing plant, ensuring a smooth business journey from conceptualization to execution. Key aspects covered include:

Market Landscape and Trends

- In-depth analysis of market dynamics, segmentation, and regional performance

- Pricing trends for raw materials and finished products

- Impact of industrial growth and regulatory changes on the TCE market

Technical and Production Insights

- Step-by-step breakdown of the trichloroethylene manufacturing process

- Machinery specifications for fully-automated, semi-automated, and manual setups

- Infrastructure, manpower, and utility requirements

- Quality control measures and compliance with industry standards

Financial and Economic Considerations

- Investment analysis, including capital expenditure and operating costs

- Profitability projections and return on investment (ROI) estimates

- Break-even analysis and strategic financial planning for long-term sustainability

Sustainability and Market Evolution

Trichloroethylene (TCE) is a volatile chlorinated hydrocarbon widely used as an industrial solvent. While it plays a crucial role in degreasing and chemical synthesis, its environmental and health impacts raise critical sustainability concerns. Therefore, integrating sustainability into its manufacturing process is increasingly essential.

a. Environmental Impact

-

Air Emissions: TCE is a VOC (Volatile Organic Compound) and can contribute to ozone layer depletion and air pollution.

-

Water Contamination: Accidental leaks or improper disposal can lead to groundwater contamination.

-

Waste Management: By-products like hydrochloric acid and other halogenated compounds need responsible disposal or recycling.

b. Sustainable Manufacturing Practices

-

Closed-loop Production Systems: Using advanced containment systems reduces emissions and exposure.

-

Energy Efficiency: Adoption of energy-efficient equipment and heat recovery systems reduces the plant’s carbon footprint.

-

Raw Material Sourcing: Sustainable feedstock like ethylene and chlorine sourced from eco-friendly suppliers supports green production goals.

-

Waste Minimization: Recycling unreacted materials and capturing solvents improve overall sustainability.

c. Regulatory Compliance

-

Manufacturers are required to comply with stringent regulations from organizations like the EPA (Environmental Protection Agency), OSHA, and REACH regarding emission levels, worker safety, and storage.

-

There’s a growing need to transition toward green chemistry alternatives or use TCE in a way that meets all evolving environmental standards.

2. Market Evolution of Trichloroethylene

The TCE market is undergoing significant transformation due to shifts in industrial demand, regulatory pressure, and technological innovation.

a. Historical Usage and Industrial Demand

-

Traditionally, TCE has been used extensively in metal degreasing, adhesives, chemical intermediate production, and dry cleaning.

-

However, many applications—particularly in consumer-facing products—have been restricted due to health and safety concerns.

b. Shifting Demand Dynamics

-

Decline in Traditional Markets: The use of TCE in dry cleaning has drastically reduced due to alternatives like perchloroethylene and green solvents.

-

Growth in Niche Applications: TCE is still in demand as an intermediate in refrigerant production (e.g., HFC-134a) and in pharmaceutical synthesis.

-

Emerging Markets: Developing countries in Asia-Pacific, Latin America, and Africa show moderate growth due to industrial expansion and lax regulations compared to Western markets.

c. Technological and Product Innovations

-

Green Solvent Alternatives: Biodegradable and less toxic solvents are emerging, leading to declining dependence on TCE.

-

Process Optimization: Advances in catalytic chlorination and energy-efficient processes are improving the cost-effectiveness and environmental footprint of TCE manufacturing.

d. Regulatory and Policy Trends

-

Governments are increasingly tightening controls on TCE due to its classification as a Group 1 carcinogen by the IARC (International Agency for Research on Cancer).

-

Some regions like the EU and California have proposed bans or strict use restrictions, accelerating the market shift toward alternatives.

3. Future Outlook

a. Sustainable Transition

-

The Trichloroethylene industry is at a crossroads: embracing sustainable manufacturing while adapting to shrinking traditional markets.

-

Long-term viability hinges on investments in environmental technologies, regulatory alignment, and product diversification.

b. Market Adaptation

-

Companies are diversifying into safer solvents or derivatives that offer similar industrial benefits with fewer health and environmental risks.

-

Strategic mergers and acquisitions in the specialty chemical space may consolidate TCE production to a few compliant, large-scale players.

c. Opportunity in Innovation

-

Innovations in waste capture, green solvent production, and circular chemical manufacturing can allow TCE plants to remain competitive.

-

Forward-thinking manufacturers may reposition themselves as leaders in low-toxicity solvent solutions, retaining market relevance while supporting sustainability goals.

Why Choose Procurement Resource?

Procurement Resource stands out as a leading provider of procurement intelligence, offering data-driven insights to help businesses make smart and strategic decisions. With a team of expert analysts and researchers, the company specializes in:

- Market intelligence and price trend analysis

- Cost modeling and feasibility studies

- Supply chain tracking and efficiency solutions

- Real-time data insights for procurement optimization

Get a Free Sample Report Today!

For businesses and investors looking to capitalize on the growing trichloroethylene market, Procurement Resource’s comprehensive report serves as an invaluable tool for making strategic and profitable investment choices.

Request a Free Sample Report Now: https://www.procurementresource.com/reports/trichloroethylene-manufacturing-plant-project-report/request-sample

Contact Information

Company Name: Procurement Resource

Contact Persons: Ashish Sharma (Sales Representative)

Email: sales@procurementresource.com

Location: 30 North Gould Street, Sheridan, WY 82801, USA

Phone:

UK: +44 7537171117

USA: +1 307 363 1045

Asia-Pacific (APAC): +91 8850629517