In the realm of industrial machinery, materials play a pivotal role in determining efficiency, longevity, and performance. Among the various materials used, ABS plastic sheets have emerged as a favored choice due to their exceptional properties. Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer that boasts a unique combination of strength, resilience, and ease of fabrication. This article delves into the critical role that ABS plastic sheets, specifically the 3/8 ABS plastic sheet and the 1/4 inch ABS plastic sheet 4×8, play in the industrial sector. Additionally, we will explore the contributions of renowned ABS sheet manufacturers in India, who are delivering high-quality products tailored to diverse industrial applications.

Characteristics of ABS Plastic Sheets

One of the defining attributes of ABS plastic sheets is their durability. They exhibit excellent impact resistance, making them ideal for components exposed to rough handling or high-stress environments. ABS sheets maintain their structural integrity even under mechanical stress, which is crucial in machinery components that operate at high speeds or under heavy loads.

Furthermore, ABS plastic sheets possess good thermal stability, allowing them to withstand elevated temperatures without losing their mechanical properties. This feature is particularly beneficial for machinery that generates significant heat during operation. The versatility of ABS also extends to its resistance to various chemicals, enabling it to withstand exposure to oils, greases, and solvents commonly found in industrial settings.

Applications in Industrial Machinery

1. Protective Covers and Panels

One of the most common applications of ABS plastic sheets in industrial machinery is in the manufacturing of protective covers and panels. These components shield sensitive machinery parts from dust, debris, and other environmental hazards that can lead to operational inefficiencies or damage. The lightweight yet sturdy nature of ABS allows for easy installation and maintenance while ensuring that machinery remains protected over time.

For example, a 1/4 inch ABS plastic sheet 4×8 is often used to fabricate covers for electrical components and machinery housings. The size of these sheets allows them to be processed into custom shapes needed for specific machines.

2. Machined Components

ABS plastic sheets can be machined into various components that play a vital role in machinery. The ease of machining allows for the creation of intricate parts, such as gears, brackets, and spacers. Utilizing a 3/8 ABS plastic sheet, for instance, allows engineers to create components that can absorb vibrations and reduce noise, enhancing the operational stability of machinery.

Additionally, components made from ABS can reduce wear on interacting parts, leading to a longer lifespan for machinery and fewer maintenance requirements. This cost-effectiveness is a compelling argument for manufacturers to consider ABS for their production processes.

3. Housings for Electrical Equipment

Electrical machinery often requires housings that protect sensitive components from environmental factors. ABS sheets provide an excellent solution due to their insulating properties and resistance to moisture and chemicals. The combination of these features makes ABS an ideal material for producing enclosures for electronic devices, control panels, and distribution boxes.

Manufacturers frequently utilize the durability of ABS sheets to create rugged housings that can withstand the rigors of industrial environments, thereby ensuring the safety and longevity of electrical equipment.

Advantages of Using ABS Plastic Sheets

Cost-Effectiveness

One of the predominant reasons manufacturers gravitate towards ABS sheets is their cost-effectiveness. Compared to other materials such as metals, ABS is relatively inexpensive while still providing exceptional strength and durability. This makes it a particularly attractive option for manufacturers aiming to reduce production costs without compromising on quality.

Customizability

ABS plastic sheets are highly customizable. They can be easily cut, shaped, and machined to meet specific requirements. This adaptability extends to different thicknesses, such as the commonly used 1/4 inch or 3/8 dimensions, making it possible for manufacturers to specify their needs accurately.

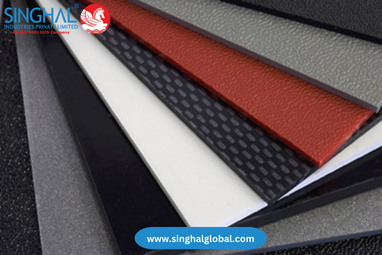

Moreover, ABS sheets can be adapted in terms of color and texture, giving designers the flexibility to meet aesthetic and functional requirements in various applications.

Environmental Resistance

In industrial environments, exposure to chemicals and weathering is a common challenge. ABS plastic sheets are resistant to a range of chemicals, oils, and grime, making them suitable for use in demanding conditions. Their ability to resist corrosion further extends the life expectancy of machinery components.

The Role of Manufacturers in India

India has seen significant growth in the manufacturing sector, with numerous ABS sheet manufacturers emerging to meet the escalating demand for high-quality plastic materials. These manufacturers leverage state-of-the-art production techniques and stringent quality control measures to ensure that the ABS sheets produced meet international standards.

Among the notable advances by Indian manufacturers is the ability to provide customized solutions. Whether it’s a specific thickness or tailored dimensions, companies can work directly with clients to ensure that products are crafted according to exact specifications. This bespoke approach enhances the utility of materials across various industrial applications.

Moreover, Indian ABS sheet manufacturers contribute positively to sustainability efforts by adopting eco-friendly practices within their manufacturing processes. By utilizing recycled materials and minimizing waste, they help lessen the environmental impact while ensuring that industries have access to durable and reliable materials for machinery.

Conclusion

In conclusion, the role of ABS plastic sheets, including the 3/8 ABS plastic sheet and the 1/4 inch ABS plastic sheet 4×8, is critical within industrial machinery applications. Their remarkable characteristics—durability, thermal stability, and resistance to chemicals—make them a favored choice for protective covers, machined components, and electrical housings. The contributions of ABS sheet manufacturer in India cannot be overlooked, as they not only provide high-quality materials but also cater to the specific needs of various industries. As the demand for resilient materials grows, the importance of ABS sheets in machinery will only continue to rise, ensuring efficiency and reliability in industrial operations.

Frequently Asked Questions (FAQs)

What are ABS plastic sheets made of?

ABS plastic sheets are made from a blend of acrylonitrile, butadiene, and styrene, making them tough, impact-resistant, and easy to work with.

Can ABS plastic sheets be painted or printed on?

Yes, ABS plastic sheets can be easily painted or printed on with the right preparation and paint, allowing for customized finishes and aesthetics.

What thicknesses are available for ABS plastic sheets?

ABS plastic sheets are available in various thicknesses, including 1/4 inch, 3/8 inch, and more, with dimensions typically standardized at 4×8 feet.