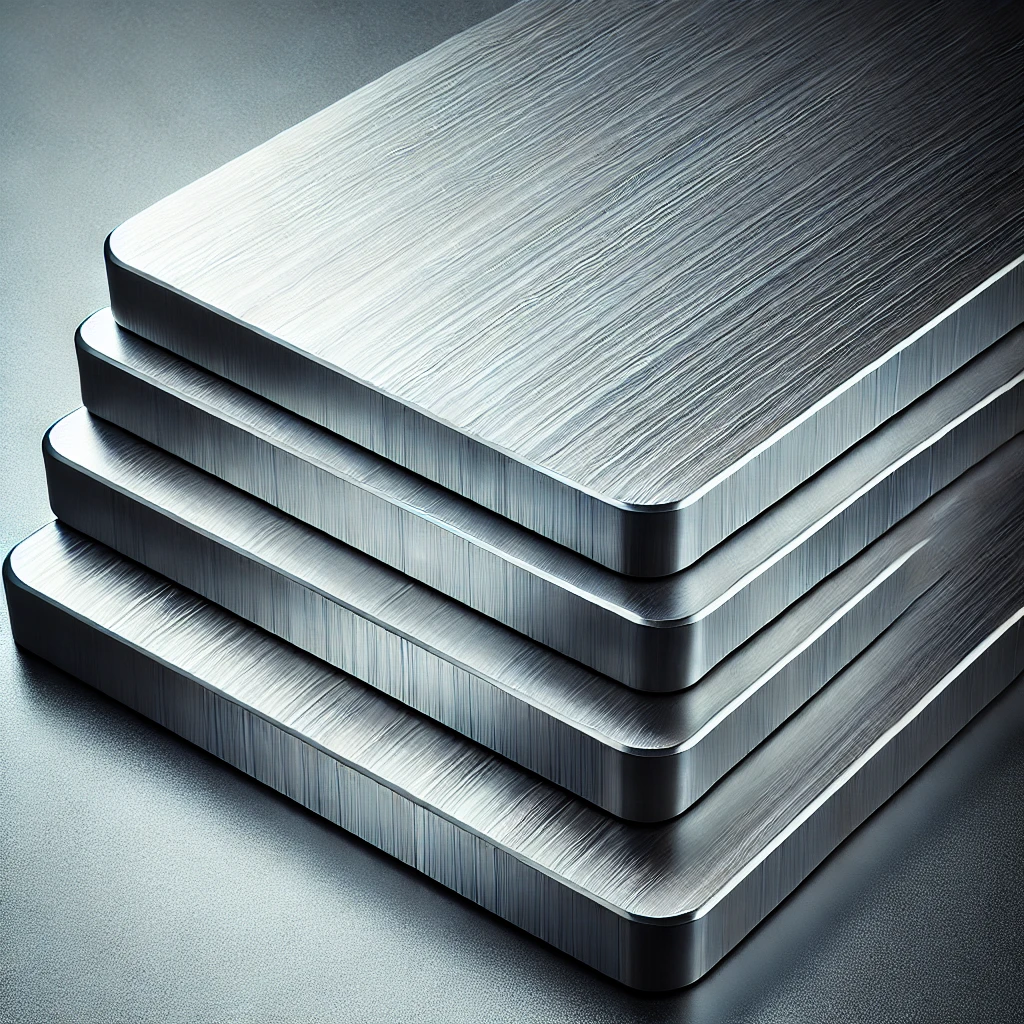

Superalloys in the family called Inconel are best known for their resistance to high temperatures and corrosive environments. Primarily a composition of nickel, these alloys are enhanced with chromium and molybdenum elements, placing them highly in industries demanding strength, durability, and resistance to corrosion. Among the numerous Inconel alloys, one stands out for its special properties, making it suitable for industries such as oil and gas, marine, and chemical processing. If you’re looking at Inconel for your next project, knowing whether it’s rust-proof is important, especially when choosing the right Inconel 925 plates supplier.

What Makes Inconel Rust-Resistant?

Rust, or iron oxide, is formed when iron reacts with oxygen in the presence of water or moisture. This is very common in metals such as steel, where the protective properties of the more advanced alloys are missing. Inconel alloys are designed to prevent rust formation since they contain elements that promote the formation of a protective oxide layer on the surface. This acts as a shield that prevents corrosive agents from reaching the metal beneath, thereby significantly reducing the chances of rust.

Inconel 925 mainly consists of nickel, which is added to the elements of chromium and molybdenum. These added elements increase its oxidation resistance. Exposed to air, chromium within the alloy forms a self-renewing oxide that is extremely thin but quite stable and tightly adherent to the metal structure. It prevents the penetration of oxygen and other corrosion factors into the metal, so it stops rust from beginning its initiation from within. These plates of Inconel 925 are, hence, useful in applications that experience a high moisture and aggressive chemical environment.

Is Inconel Rust-Proof?

Of course, no metal is rust-proof, but among the top options for high corrosion resistance is Inconel 925. The protective oxide layer that it forms is almost permanent in most environments and, thus, will not be affected by rust. However, similar to any other material, there is always the possibility of the protective integrity breaking down in extreme exposure to either very high temperatures for a longer period of time or extreme acidity and alkalinity environments. This causes the layer to thicken over time, and, depending on environmental conditions, this layer will eventually wear out, causing the corrosion layer to affect the base metal.

Even though it may have its weaknesses, Inconel 925 plates have much more resistance to rust as compared to other metals. It is really valuable for use in critical applications, especially where reliability and long life are prime considerations, once it undergoes routine maintenance and cleaning.

Advantages of Inconel 925 Plates in Rust Prone Conditions

High Corrosion Resistivity

Being highly rich in both nickel and chromium, inconel 925 offers protection for high-oxidative as well as corrosive applications to ensure the work environment, like at an oil rig’s chemical plant and in contact with seawater. By virtue of the increased anti-corrosion property of the above alloy, maintenance costs can also be considerably reduced, and service lives can increase so ideal applications include long-term projects.

Resistance to Pitting and Crevice Corrosion

With high molybdenum content, Inconel 925 enhances its performance towards localized corrosion, and its properties are pitted corrosion as well as crevice corrosion. These properties tend to occur in those chemical compounds containing chlorides, where corrosion cannot hinder the performance of the material exposed in sea water or various types of chemicals containing chlorine.

Resistance to High-Temperature Corrosion:

Another significant advantage of Inconel 925 plates is that they do not deteriorate at high temperatures. The alloy maintains its strength and corrosion resistance at elevated temperatures, thus making it an ideal choice for applications in heat exchangers, gas turbines, and other high-temperature environments.

Resistance to Corrosion and Durability

Due to its unique composition, Inconel 925 offers excellent toughness, meaning that it has to be replaced less often. This saves time and reduces costs in the long run. For industries such as oil and gas, which require constant and reliable performance, the use of Inconel 925 plates can be a critical difference.

Finding a Reliable Inconel 925 Plates Supplier

The quality and specification of Inconel 925 plates depend on the supplier from whom you would obtain your plates. Here are a few things that you may want to look into for a supplier:

Excellent History: Suppliers with good experience and history of supplying good quality Inconel products should be sought after. Customer reviews, feedbacks, and references in relevant industries can give you some idea about their credibility.

The certified products that could be expected from the finest supplier of Inconel 925 plates must indeed have met industrial standards either through ASTM or ASME. It would, hence, be sure that their quality and guarantee really meet a specific requirement for which the product is expected in industries.

A good supplier should supply many kinds of sizes and thicknesses. Variety can give assurance that you will find the specifications you need for your project without compromising the quality.

Technical Support: Select a supplier who can give technical consultancy, be it the recommendation of the correct Inconel grade or assistance in manufacturing and installation. Knowledgeable suppliers will be able to help you get the best possible output and more life out of your Inconel 925 plates.

Uses of Inconel 925 Plates in Corrosive Environments

Since Inconel 925 is corrosion resistant, this alloy is widely used in industries where resistance to corrosion is greatly needed:

Oil and Gas: The Inconel 925 plates are used exhaustively in offshore drilling equipment and extraction apparatus as the salty environment of sea, with pressure, poses no problem.

Marine Applications: The presence of Inconel 925 makes vessels and other marine products resistant to the corrosion action of seawater, and the alloy is used abundantly in making valves and pumps.

Chemical Processing: The chemical resistance property of Inconel 925 makes it one of the most sought materials for chemical processing plants that face aggressive acids and chlorides from equipment.

Aerospace: High-temperature resistant Inconel 925 plates also have the ability to find application in aerospace industries, especially at points where the components experience extreme temperatures and harsh environment conditions.

Conclusion

Though no alloy is completely rust-proof, Inconel 925 plates come very close to achieving this. Their ability to withstand corrosion, particularly in severe environments, has led them to be regarded as one of the most dependable choices for industrial uses. Be it marine or chemical plants, Inconel 925’s ruggedness means that corrosive factors that would otherwise mar the performance of other metals have no effect on Inconel 925.

It is therefore imperative that one chooses a credible provider of Inconel 925 plates so as to have the best material regarding the stringent demands on a particular project. From right provision and maintenance of one’s Inconel-based products, you get benefits to the maximum degree concerning the exceptional alloy used: the efficiency over a longer span without the frequent requirement to replace.

In conclusion, Inconel 925 plates represent an excellent solution to any person who wants reliability and long service life due to rust resistance in a very adverse environment. As long as the right supplier is in place, this performance cannot be matched anywhere, and it is almost like an investment in future generations of any high-stakes industrial application.

For more information visit our website : https://technonetwork.co.in/