What distinguishes a PLC from a DCS is among the most often asked questions in industrial control and automation systems. We must examine the development of Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC) and dissect their internal workings in order to completely comprehend the differences between these two systems.

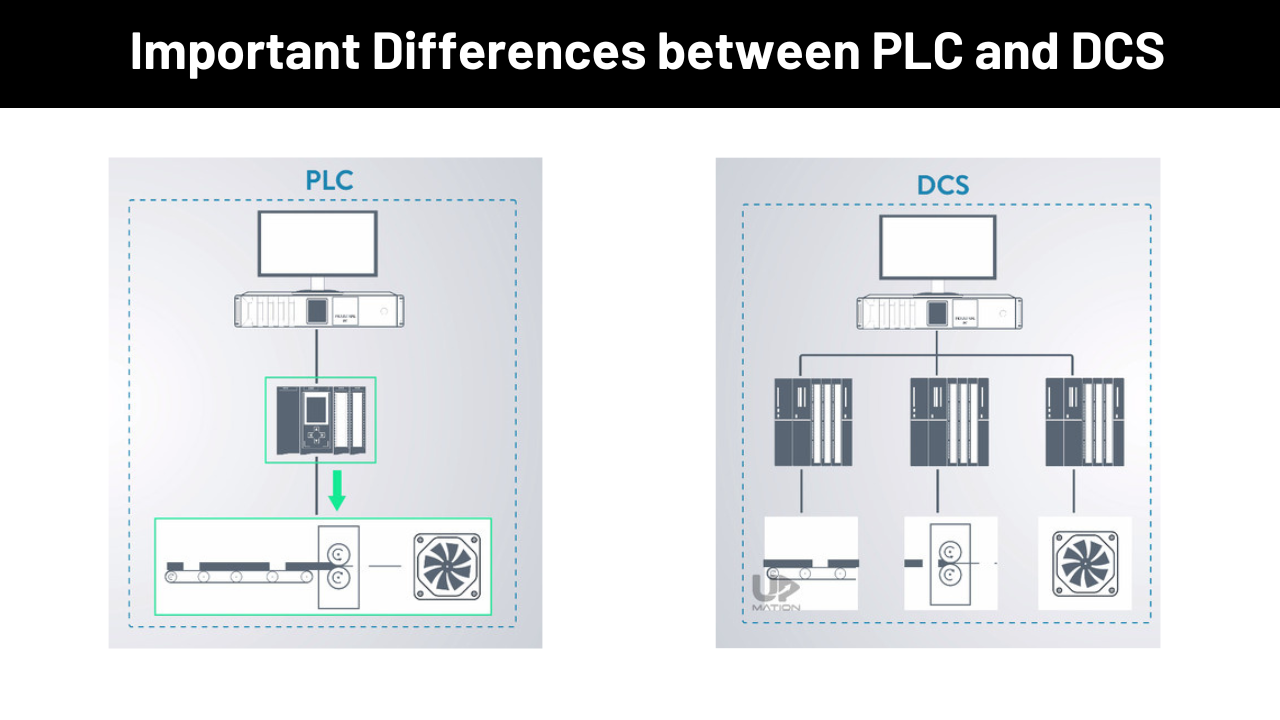

The primary distinction between a PLC and a DCS is that a PLC manages a single machine, whereas a DCS manages numerous machines in a factory or plant. This is merely a brief explanation, though. Let’s dig a little further and look at the significant distinctions that are less well-known.

History of Programmable Logic Controllers

Relays were the only means of machine control prior to the invention of the PLC. Relays function by using a coil that, when powered up, generates a magnetic field that successfully pulls a switch into the ON or OFF position. The switch releases and resets the gadget to its usual ON or OFF position when the relay is de-energized. Thus I could place a relay between the power source and the motor, for instance, if I wanted to control whether a motor was ON or OFF. Then, by turning on or off the relay, I may regulate when the motor receives power. Of course, the motor would not operate without power, therefore I am in charge of it. This particular relay is what would you do if there were multiple motors that needed to be regulated in one factory? You assemble numerous power relays. As a result, industries began to assemble electrical cabinets packed with power relays. But wait, how do the power relay coils turn ON and OFF before turning on the motor, and what if I want to control that? How do you behave? add more relays. Because they manage the relays that manage the switch that turns the motor ON and OFF, these relays are referred to as control relays. I could go on, but I think you get the idea of how machines were controlled before to the invention of the Programmable Logic Controller (PLC), and more significantly, I think you start to see some of the issues with this.

How Distributed Control Systems Evolved

The early 1960s saw a continued expansion of process control. The biggest difference came when the corporation Imperial Chemical Industries replaced its analogue monitoring system with a computer. This indicated that rather of having an analogue system supervise the operations, a computer might actually carry out the control functions. Direct Digital Control (DDC) is the name given to this idea, which proved to be more efficient and cost-effective. DDC languages emerged in large numbers. It became well-known for its application in building automation chores like heating and ventilation due to its simplicity. Even today, the early DDC languages remain the foundation of DCS systems.

The fundamental goal of technological development up to the 1980s had been to replace analogue control systems with computers. The next stage was to establish a centralized system where everything could be managed, even if this was a new idea. One of the first businesses to accomplish this was Midac, which developed a sophisticated building automation system for the University of Melbourne. The system utilized a network of microprocessors that shared memory and tasks.

However, DCS firms learnt to become more software oriented in the 1990s due to Microsoft’s dominance, realizing that it was no longer profitable to continue producing some of the hardware. This is still the case today.

The Major Differences Between the PLC and DCS

PLC operating systems are quite basic. They may accomplish things reasonably rapidly because there are no other programs in the background requesting its attention. Due to their proximity to the machinery they are designed to regulate, such as motors and pumps, PLCs also have a tendency to operate more quickly. PLCs may concentrate their attention on a particular task and manage machine processes while controlling a single machine. Compared to a DCS, which manages numerous machines concurrently in a big space, this is very different.

Furthermore, PLCs, as opposed to DCS, are typically more versatile and can be tailored to meet a particular demand. PLCs frequently employ low level languages. They have fewer functionality yet being simple. This incorporates structured text language, function block diagrams, and ladder logic. In comparison to the codes produced by the DCS languages, the resulting codes are noticeably smaller. High-level programming languages, such as CFC or “continuous functioning chart,” are used by DCS to create its programming and monitor its operations. Comparing this to a PLC, which use lower level language, is extremely different. This has the drawback of taxing the CPU because high-level languages produce a lot of code after being generated. Important inputs are delayed as a result of this.

DCS vs. PLC Explained

The primary distinction between a PLC and a DCS is that the former was created to take the place of analogue machinery and relay-based controls. On the other hand, DCS are used to manage huge, linked plants, structures, or processes as a whole. While the usage and purpose of DCS and PLC differ primarily, there are other less visible differences that those who are interested in this field should be aware of.

As a PLC technician, understanding these differences will make you stronger in your job and build up your competence. Check out our PLC Technician Training Program if you’re interested in learning more and broadening your understanding of the fascinating world of PLCs. The curriculum is excellent for those who are new to PLCs or who already have experience in the sector and prepares students for a career as a PLC technician.

This article in the Havily must have given you a clear idea about what is Differences between PLC and DCS and how it can help in automation industry to achieve their goals faster and more efficiently.