When it comes to brass products, quality is key. Suppliers in Northern California have built a strong reputation by focusing on quality control. Brass is used in many areas, like plumbing, electrical work, and decorative pieces. To make sure their products meet high standards, suppliers follow a detailed process. But what exactly do they do to keep quality in check?

This article will show you how Brass Northern California suppliers ensure product quality. We’ll break it down into simple steps so it’s easy for everyone to understand.

- Sourcing the Best Raw Materials

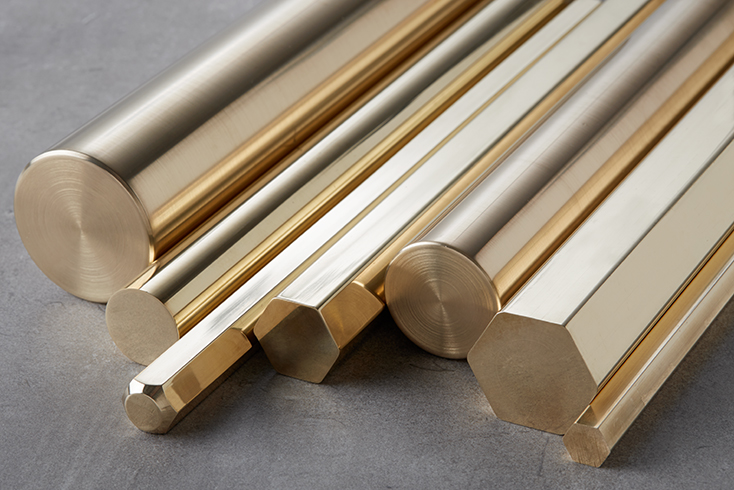

A good product starts with good materials. Brass is made from copper and zinc. Northern California suppliers choose their raw materials carefully. They work with trusted sources that meet strict standards. By using high-quality copper and zinc, they ensure that their brass is strong, durable, and resistant to corrosion.

Some suppliers choose U.S.-based metal sources. These sources are known for their strict regulations and high quality. This guarantees that the final product will be reliable and consistent.

- Using Advanced Manufacturing Techniques

To create high-quality brass, suppliers use modern machines and tools. Techniques like casting, extrusion, and forging help produce uniform products. This means that each brass piece looks and performs the same.

Machines like CNC (Computer Numerical Control) systems help shape brass with great accuracy. This reduces mistakes and ensures that each piece meets the required specifications.

- Testing Each Product Thoroughly

Testing is a big part of quality control. Before shipping, each brass product goes through many tests. These tests check for strength, composition, and surface quality. Some common tests include:

- Chemical Analysis

Ensures the right balance of copper and zinc.

- Strength Testing

Checks if the brass can handle stress and pressure.

- Visual Inspection

Looks for surface flaws like cracks or discoloration.

These tests help suppliers maintain a high level of product quality.

- Following Industry Standards

Many Northern California brass suppliers follow strict industry standards. Some common standards include those set by ASTM (American Society for Testing and Materials). These guidelines help ensure that brass products are safe and reliable.

Some suppliers also hold ISO (International Organization for Standardization) certifications. This means their processes meet global standards. Following these guidelines helps suppliers create high-quality products and keep their customers happy.

- Caring for the Environment

Quality is not just about the final product. It’s also about how it’s made. Many Northern California suppliers follow eco-friendly practices. This can include using energy-efficient machines and recycling leftover materials.

Recycling brass reduces waste and helps the environment. Suppliers can melt down leftover pieces and use them again. This helps maintain product quality and lowers production costs.

- Training Skilled Employees

Skilled employees are key to creating quality products. Northern California suppliers invest in their workers. They provide training on the latest techniques and safety measures.

Experienced workers can spot and fix issues quickly. This reduces the chance of errors during production. It also means fewer defective products reach customers.

- Listening to Customer Feedback

Customer feedback helps suppliers improve. Suppliers often ask their clients for input on their products. If there is an issue, they look into it and make changes. This focus on feedback helps them keep their customers satisfied and loyal.

For example, if a customer reports a problem with a product, the supplier investigates. They find the root cause and fix it. This prevents the same problem from happening again.

- Investing in Research and Development

Many suppliers invest in research and development (R&D). This helps them create new products and improve existing ones. R&D allows suppliers to find better ways to produce brass, making it stronger or more resistant to wear.

This investment helps them stay ahead in the market. It also ensures they can meet the changing needs of their clients.

- Choosing Reliable Logistics Partners

Good logistics are important for maintaining quality. Northern California suppliers work with reliable shipping partners. This helps them deliver products on time and in good condition.

Proper handling and shipping reduce the risk of damage. By using trusted logistics providers, suppliers make sure their products reach customers safely.

- Providing Excellent Customer Support

Customer support is a big part of quality. A good supplier will not only sell high-quality products but also offer support. They help clients choose the right products, answer questions, and provide technical help.

This focus on customer service builds trust. It also shows the supplier’s commitment to quality and customer satisfaction.

Conclusion

Brass Northern California take many steps to ensure product quality. They start with high-quality materials and use advanced techniques. They test each product thoroughly and follow strict industry standards. By investing in skilled employees, caring for the environment, and listening to customer feedback, they maintain a high level of quality. Thank visiting technonetwork.co.in