In the modern world of manufacturing, precision and efficiency are key to producing high-quality products. One of the most effective methods for achieving these goals is through CNC (Computer Numerical Control) turning. CNC turning services have revolutionized industries by providing unparalleled accuracy, repeatability, and versatility in the production process. This article explores how CNC turning services can significantly improve product quality, enhance production efficiency, and contribute to overall business success.

What is CNC Turning and How Does It Work?

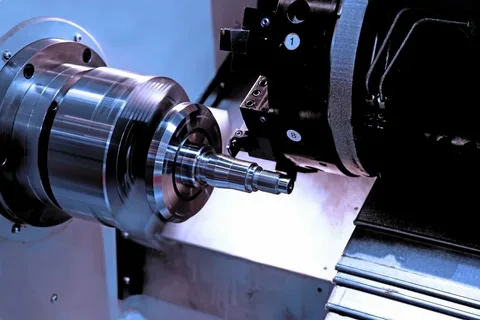

CNC turning is a machining process that uses computer-controlled lathes to shape and cut materials into cylindrical or spherical shapes. The machine automatically controls the movement of tools and the workpiece, ensuring precise cuts and consistent results. In CNC turning, the workpiece is rotated while the cutting tool moves along different axes to remove material. This allows manufacturers to create complex shapes with tight tolerances, making it an ideal choice for producing high-quality components used in a variety of industries, including aerospace, automotive, and medical.

Unlike manual turning, which requires a skilled operator to adjust and monitor the machine, CNC turning is entirely automated. This means that once the design specifications are programmed into the system, the CNC machine can produce identical parts with remarkable consistency. The precision offered by CNC turning services ensures that the final product meets exact measurements, which is essential for applications where quality control and safety are paramount.

Enhanced Precision and Accuracy

One of the most significant advantages of CNC turning services is the exceptional precision and accuracy they provide. CNC machines can perform intricate tasks with a high degree of consistency, allowing manufacturers to meet tight tolerances that are difficult to achieve with traditional methods. This level of precision is especially important when working with complex designs or parts that require exact dimensions for proper functionality.

By utilizing CNC turning, manufacturers can produce components that are virtually identical, reducing the likelihood of defects and ensuring that each part fits seamlessly with other components. This high level of accuracy not only improves the overall quality of the product but also minimizes the need for rework or scrapping of parts, which can be costly and time-consuming. Ultimately, this contributes to better product quality and more efficient production processes.

Increased Production Efficiency

CNC turning services can significantly improve production efficiency, which is crucial for businesses looking to stay competitive in today’s fast-paced market. CNC machines are designed to operate continuously with minimal human intervention, which reduces the risk of errors and increases throughput. With CNC turning, the production process becomes highly streamlined, allowing manufacturers to produce large quantities of parts in a shorter amount of time without compromising quality.

Furthermore, CNC turning machines are capable of performing multiple operations simultaneously. For example, they can handle tasks such as drilling, milling, and threading, all within a single setup. This versatility not only saves time but also reduces the need for multiple machines or setups, further improving overall efficiency. The ability to automate the manufacturing process also results in fewer delays and interruptions, ensuring that products are delivered on time and to the highest quality standards.

Versatility in Material Selection

CNC turning services offer exceptional versatility when it comes to the types of materials that can be used in the manufacturing process. CNC lathes can handle a wide range of materials, including metals, plastics, and composites, each with varying levels of hardness and durability. This flexibility enables manufacturers to select the most suitable material for their specific application, ensuring the final product meets the desired performance characteristics.

Whether the product requires lightweight aluminum, durable steel, or high-performance polymers, CNC turning machines can adapt to different materials with ease. The precise nature of CNC turning ensures that even challenging materials can be machined to the required specifications. This versatility not only improves the quality of the product but also opens up opportunities for innovation and design improvements in a variety of industries.

Cost-Effective Production and Waste Reduction

While the initial investment in CNC turning equipment may seem significant, the long-term benefits make it a highly cost-effective solution. CNC turning services can help reduce costs in several ways, particularly through waste reduction and efficient use of materials. Traditional machining methods often result in a high level of material waste, especially when producing complex parts that require multiple stages of cutting. CNC turning minimizes waste by using the exact amount of material needed for each part, reducing material costs and minimizing environmental impact.

In addition to reducing material waste, CNC turning also decreases labor costs. Since the process is automated, less manpower is required to operate the machine, and the risk of human error is significantly reduced. The ability to produce parts with fewer defects and less rework further lowers costs and contributes to a more efficient manufacturing process. This cost-effective approach allows businesses to offer high-quality products at competitive prices while maintaining profitability.

Conclusion

CNC turning services have become a game-changer for manufacturers seeking to improve product quality, streamline production, and reduce costs. By offering enhanced precision, increased efficiency, versatility in material selection, and waste reduction, CNC turning plays a vital role in the success of modern manufacturing operations. Businesses that invest in CNC turning technology can deliver high-quality products that meet the demands of today’s competitive markets while also optimizing their production processes for maximum efficiency and cost-effectiveness. Whether you are producing small components or large-scale parts, CNC turning services are an essential tool for improving product quality and staying ahead in the manufacturing industry.