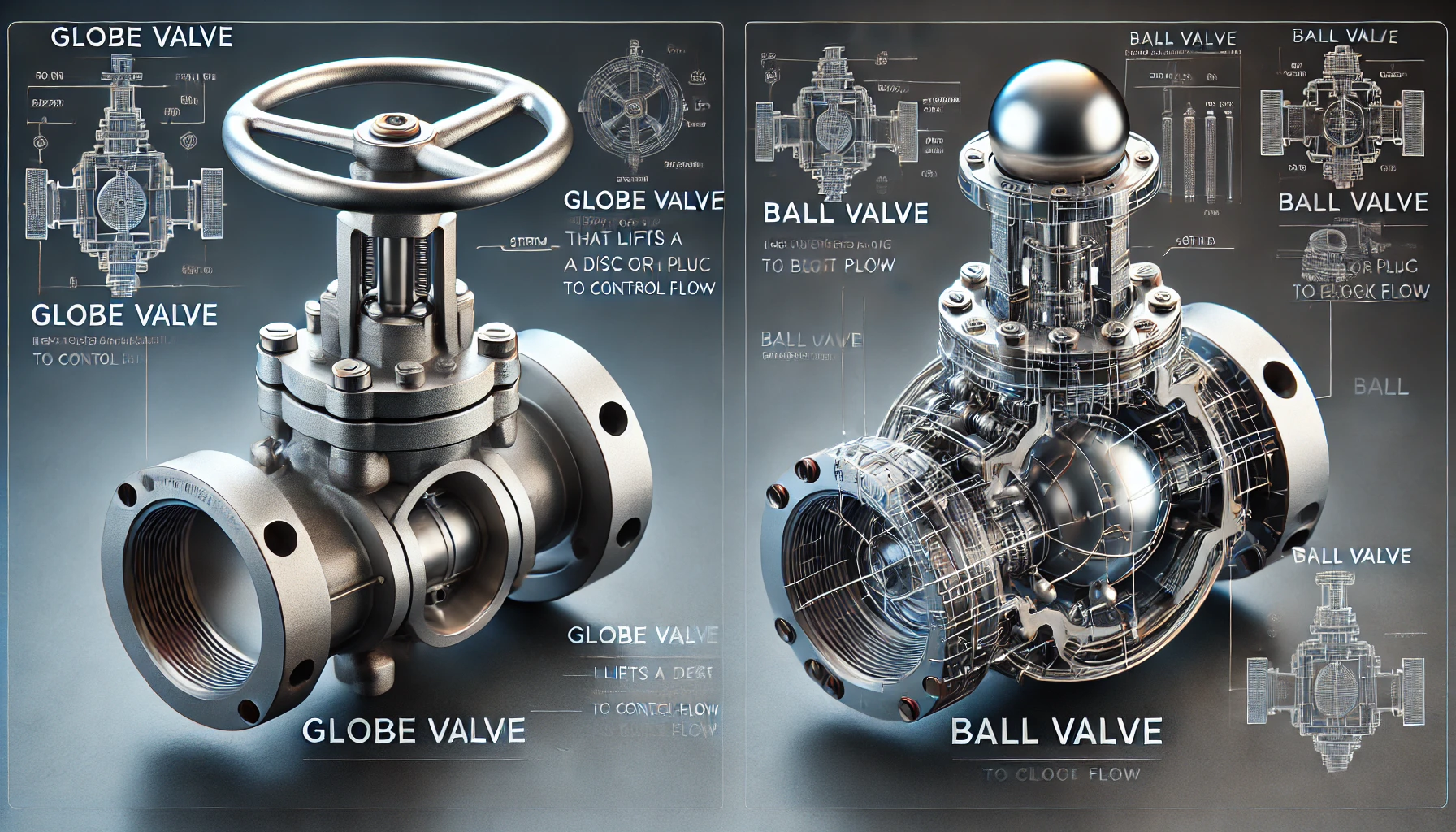

Globe valves and ball valves are the two most popular types of valves that have found wide applications in controlling flow passages in industrial applications. Both types of valves ensure important functionality in fluid control, but there is a difference in their design and operating and application principles. In this blog, let’s compare the two types of valves and discuss their main differences to help you decide which one to use in your process.

What Is Globe Valve?

A globe valve is a valve in the control of fluid flow or to throttle it. It has a spherical body, which houses a disc inside that moves perpendicular to fluid flow. Once it opens it lifts the disc to allow the liquid, and closes by pressing it against the seat stopping fluid flow.

Key Features of Globe Valves

Flow Control: Globe valves are ideal for flow control, it actually controls the amount of fluid flowing through the valve with accuracy.

Working: The handwheel turns, this raises or lowers the disc inside the valve. The more you turn the handwheel the more open or closed the valve becomes.

Applications: Globe valves are majorly used in applications that require throttling. The most common ones include cooling systems, fuel lines, or even a water distribution system.

Globe Valve Advantages

Precise Flow Regulation: The most important advantage of a globe valve is its capability for precise flow regulation, which makes it apt for applications that call for frequent adjustment.

Long Period Use: Globe valves are built to have the ability to work effectively at high pressure and high temperatures, which makes them durable for a range of industrial usage.

Good Shutoff: Once closed, the globe valve will have a tight shutoff with no leakage.

What is a Ball Valve?

A ball valve, in turn, is a quarter-turn valve that uses a spherically shaped ball with a centre hole to control fluid flow. On a 90-degree turn of the valve handle, the center hole points toward the flow, and fluid flows through. When one turns the handle back, the hole faces the flow orthogonally, cutting off the fluid.

Important Characteristics of Ball Valves

Ball Valve Fast Operation: Ball valves don’t need extensive periods of manipulation. A 90-degree turn completely opens or closes the valve.

Tight Seal: The sealing offered by the ball valve is tight. Ball valves are highly useful wherever a complete shutdown is involved.

Applications: They are used in pipelines, gas pipes, and places where immediate on/off control is needed.

Advantages of Ball Valves

Ease of use is one of the significant advantages of a ball valve. It has a quarter turn to fully open or close the valve, making it perfect for fast shutoff needs.

Ball valves offer minimal resistance towards fluid flow, which gives it a lower pressure drop when the valve is open.

Reliability: Ball valves are less worn out compared to globe valves, hence very reliable for a long period.

Key Difference Between Globe Valve and Ball Valve

Working: Globe valves are mainly used for throttling. In the globe valve, fluid flow control is much better compared to a ball valve.Ball valves are on/off type valves. They are not apt for throttling since they do not provide fine adjustments.

Flow Restriction: Since the fluid is deflected in the globe valve, resistance and pressure loss are higher than those in a ball valve.

At full opening, the flow through a ball valve will be almost negligible with zero restriction as the fluid travels straight through the valve.

Sealing:Ball valves are much tighter in seal than globe valves. They are, therefore, used where 100% shutoff is the primary consideration. Globe valves are suitable for flow control applications but will not shut as tight when fully closed.

Operation Speed: Ball valves operate faster than globe valves because they only require 90 degrees to open or close fully.

For instance, globe valves require more turns of the handwheel and, therefore take a longer time to open or close.

Applications: Globe valves are applied in places where high regulation of flow rates have to be effected repeatedly; that is in chemical processing or water treatment plants.

Ball valves are mainly utilized in a system to shut off quickly. Ball valves are utilized in oil and gas pipelines as well as other high-pressure systems.

Valve to Select

Whether it’s a globe valve or a ball valve, it just comes down to which one will best serve the needs of the specific application. Globe valves are designed for use in situations where very precise throttling of the flow is required; if the valve has to be a rapid and complete shut-off valve without creating any restriction in the flow, then a ball valve is suited for this purpose.

Both globe valves and ball valves should have their place in the oil and gas and chemical processing industries, water treatment, as well as in other process water and chemical treatment. Understanding both strengths and weaknesses can guide you towards a better decision that will give optimum performance in your chosen application.

Follow for more : https://technonetwork.co.in/