Introduction

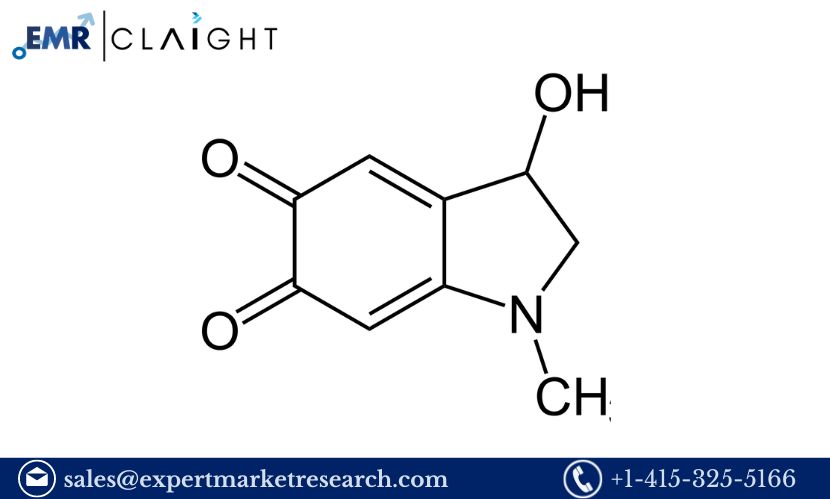

Adrenochrome, a compound derived from the oxidation of adrenaline, has gained significant attention in various circles due to its perceived effects and cultural significance. While its depiction in popular media often leans toward the fantastical, a deeper understanding of its scientific and industrial potential is necessary for a comprehensive discussion. This Adrenochrome Manufacturing Plant Project Report aims to provide an overview of an adrenochrome manufacturing plant project, including its objectives, methodologies, and potential implications.

Project Objectives

The primary objectives of the adrenochrome manufacturing plant project include:

- Establishing a Sustainable Production Process: Developing a method to produce adrenochrome efficiently and sustainably, utilizing ethical practices and ensuring environmental safety.

- Research and Development: Investigating the biochemical properties of adrenochrome to explore potential therapeutic applications, particularly in mental health and neurology.

- Regulatory Compliance: Ensuring that all manufacturing processes comply with local and international regulations concerning chemical production and safety.

- Market Analysis: Identifying potential markets for adrenochrome, including pharmaceuticals and research institutions, and analyzing demand trends.

- Community Engagement: Informing and involving local communities to address concerns about the plant’s operations and its implications.

Get a Free Sample Report with Table of Contents @

Manufacturing Process

The manufacturing process of adrenochrome typically involves several key stages:

1. Raw Material Sourcing

The primary raw material for adrenochrome production is adrenaline, which can be sourced from synthetic pathways or extracted from animal sources. Ethical considerations dictate that synthetic production is preferable to minimize animal welfare concerns.

2. Oxidation Reaction

The core of adrenochrome production involves oxidizing adrenaline. This reaction can be facilitated using various oxidizing agents in a controlled laboratory environment. The choice of reagents and reaction conditions will significantly influence the yield and purity of the final product.

3. Purification

Once the oxidation is complete, the resulting product undergoes purification. Techniques such as chromatography may be employed to isolate adrenochrome from byproducts and unreacted materials, ensuring a high-quality final product.

4. Quality Control

Quality control measures are essential to guarantee the consistency and safety of the manufactured adrenochrome. Regular testing for purity and potency is necessary to comply with pharmaceutical standards.

5. Packaging and Distribution

After passing quality control, the final product is packaged in compliance with safety regulations. Distribution channels are established to ensure timely delivery to clients in various sectors, including research institutions and pharmaceutical companies.

Market Analysis

1. Target Markets

The primary target markets for adrenochrome include:

- Pharmaceutical Industry: Potential uses in treatments for various psychological disorders are being researched.

- Research Institutions: Laboratories studying adrenaline and its derivatives for various applications.

- Specialty Chemicals: Companies that utilize adrenochrome in the manufacture of dyes or other chemical compounds.

2. Demand Trends

Recent trends indicate a growing interest in biochemical research and mental health treatment options, suggesting a potential increase in demand for adrenochrome. Ongoing studies into its effects could lead to breakthroughs in therapeutic applications.

Regulatory Compliance

Navigating the regulatory landscape is crucial for the successful establishment of the adrenochrome manufacturing plant. Compliance with local and international laws governing chemical manufacturing, environmental safety, and workplace regulations will be paramount. Engaging with regulatory bodies early in the process will facilitate a smoother operational setup.

Community Engagement

Establishing open lines of communication with local communities is essential. This includes:

- Informational Sessions: Hosting community meetings to educate the public about adrenochrome, its uses, and safety measures.

- Feedback Mechanisms: Creating avenues for residents to express concerns or suggestions regarding the plant’s operations.

- Sustainability Initiatives: Implementing eco-friendly practices to minimize the plant’s environmental footprint.

FAQ

1. What is adrenochrome?

Adrenochrome is a compound formed by the oxidation of adrenaline. It has been the subject of various studies exploring its effects on the human body, particularly concerning mental health.

2. Is adrenochrome safe for consumption?

Research on the safety and effects of adrenochrome is still ongoing. It is crucial to consult medical professionals before considering its use, as safety can vary depending on individual health conditions.

3. What are the potential uses of adrenochrome?

Potential uses include applications in mental health treatment and research, as well as uses in specialized chemical manufacturing.

4. How is adrenochrome manufactured?

Adrenochrome is produced through the oxidation of adrenaline, followed by purification and quality control measures to ensure safety and efficacy.

5. Are there ethical concerns associated with adrenochrome production?

Ethical concerns mainly revolve around the sourcing of adrenaline and the potential implications of its use. Synthetic production methods are preferred to address these issues.

6. What regulations must be followed for adrenochrome manufacturing?

Manufacturers must comply with local and international chemical production regulations, environmental safety laws, and workplace safety standards.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au