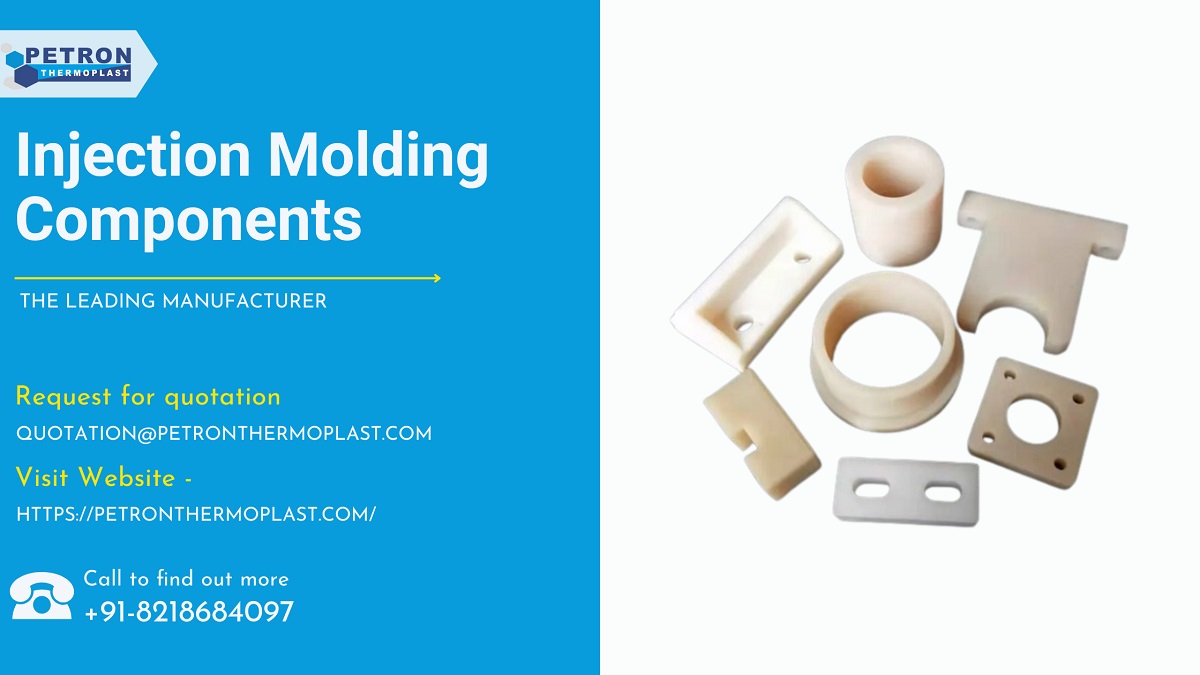

In the world of modern manufacturing, precision, durability, and efficiency are the pillars of success. Injection molding is one of the most versatile and widely used methods for producing high-quality plastic components. As industries continue to demand innovative, custom solutions, Petron Thermoplast stands at the forefront as a leading manufacturer of injection molding components, providing exceptional products that meet the diverse needs of various sectors.

The Importance of High-Quality Injection Molding Components

Injection molding has revolutionized manufacturing by enabling the production of complex, intricate parts with a high degree of precision. Whether it’s automotive, electronics, medical, or consumer goods, the success of any product depends on the quality of its components. At Petron Thermoplast, we understand the critical role that injection molding components play in the overall performance and reliability of your products.

Our extensive expertise, cutting-edge technology, and commitment to excellence make us a trusted partner for industries worldwide. We produce custom injection molding components that meet stringent quality standards and are tailored to your specific requirements.

What Sets Petron Thermoplast Apart?

Precision and Innovation

At Petron Thermoplast, we leverage advanced injection molding techniques to produce components with exceptional accuracy and consistency. Our state-of-the-art machines are capable of handling a wide range of materials, from standard plastics to high-performance thermoplastics like PEEK and UHMWPE. This allows us to create intricate, durable, and reliable components that perform in even the most demanding environments.

Custom Solutions for Every Industry

Every industry has its unique requirements when it comes to injection molding components. That’s why Petron Thermoplast offers custom solutions designed to meet your specific needs. We work closely with our clients to understand their requirements, offering flexibility in design, materials, and production volume.

Durable and Reliable Materials

One of the critical factors that influence the longevity and performance of injection molding components is the choice of material. Petron Thermoplast uses only high-quality thermoplastics, ensuring that each part we produce is strong, durable, and resistant to wear, chemicals, and extreme temperatures.

Rigorous Quality Control

Quality is non-negotiable at Petron Thermoplast. Each component that leaves our facility undergoes rigorous testing and quality control measures to ensure it meets the highest standards of performance and durability. We adhere to industry-leading quality management systems, ensuring that your products are free from defects and perform reliably under all conditions.

Sustainability in Manufacturing

As part of our commitment to sustainability, Petron Thermoplast integrates environmentally responsible practices into our production processes. From minimizing material waste to using energy-efficient technologies, we aim to reduce our environmental footprint while still delivering high-quality injection molding components. This approach not only benefits the planet but also helps our clients achieve their own sustainability goals.

Industries We Serve

Automotive

Injection molding components play a crucial role in the automotive industry, where precision, strength, and durability are vital. From interior components to engine parts, we manufacture custom injection molding components that enhance vehicle performance, safety, and efficiency.

Medical Devices

In the medical field, accuracy and reliability can be a matter of life and death. Petron Thermoplast’s injection molding components are designed to meet the stringent requirements of the medical industry, ensuring that each part meets regulatory standards and provides flawless performance in critical applications.

Electronics

For the electronics industry, where space is limited and functionality is paramount, injection molding components must be precise, lightweight, and durable. We produce components that support the manufacturing of electronic devices, circuit boards, and more, ensuring long-lasting performance.

Aerospace

Aerospace components require the highest levels of precision and performance. At Petron Thermoplast, we produce custom injection molding components that can withstand the extreme conditions faced by aerospace systems, from high altitudes to intense pressure and temperature changes.

Consumer Goods

From household products to sporting goods, injection molding is a key part of the consumer goods sector. We manufacture components that offer excellent aesthetic and functional qualities, ensuring that products look great and perform reliably.

Why Choose Petron Thermoplast?

When it comes to injection molding components, Petron Thermoplast is a name you can trust. Here’s why industries worldwide choose us as their preferred partner:

- Expertise: With years of experience in the industry, our team of skilled engineers and technicians brings unparalleled knowledge to every project.

- Advanced Technology: We use cutting-edge equipment and techniques to produce high-precision components with tight tolerances.

- Customization: No project is too complex. We work with you to create custom solutions that meet your specific requirements, from design to production.

- Quality Assurance: We maintain stringent quality control throughout the entire manufacturing process, ensuring the delivery of defect-free components.

- Timely Delivery: Our efficient production process ensures that your components are delivered on time, every time, without compromising on quality.

Conclusion

As a leading manufacturer of injection molding components, Petron Thermoplast is dedicated to providing custom-engineered solutions that drive innovation and performance across industries. From concept to completion, our focus on precision, quality, and customer satisfaction makes us the go-to partner for businesses looking for reliable, high-performance injection molding components.